Convenient and Practical

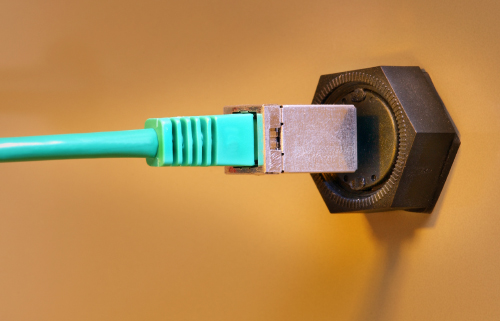

AREVA’s E-Plug hardware permits the acquisition of motor electrical signature analysis data at a motor control center (MCC) — without opening the MCC door. The user simply attaches a connector to the door, while cable from the innovative E-Plug module passes voltage and current data from probes inside the MCC to the connector. The connector then mates with a cable that permits direct feed into EMPATH 2000, expediting electrical signature analysis. The E-Plug’s efficient design comprises an enclosure with external attachment leads. Both current and voltage signals pass through these leads. Inside the enclosure, electronic circuitry processes the signals to prepare them for output to the through-door connector. In short, E-Plug contains everything you need for efficient signal transmission.

Inputs to the E-Plug Module

Power cables to the motor pass through current transducers (CTs) that measure the current flowing through the cable and produce a voltage output proportional to the current flowing to the motor. The voltage output from the current transducers is typically tens of milli-volts per amp, yielding an upper limit of 10 Vac for the current transducer output. Fused wires attached to the power cables provide a voltage signal to the E-Plug module. For supplied power up to 600 Vrms, the E-Plug module will be directly connected to the voltage signal. For supplied power above 600 Vrms, output from existing potential transformers (PTs) will step the voltage down to 120 Vrms prior to feeding to the E-Plug Module. For both voltage and current measurements, the frequency response is DC to 5000 Hz, minimum.